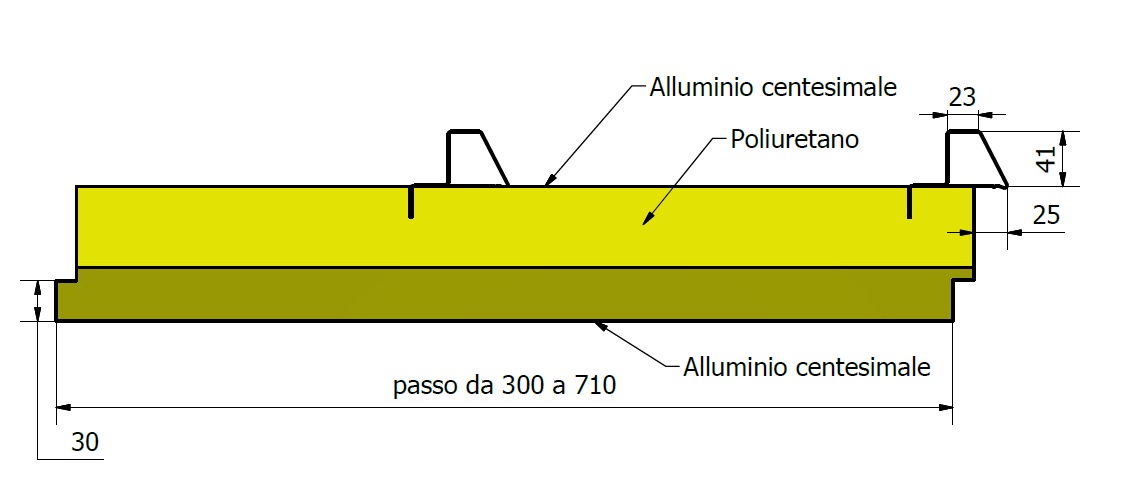

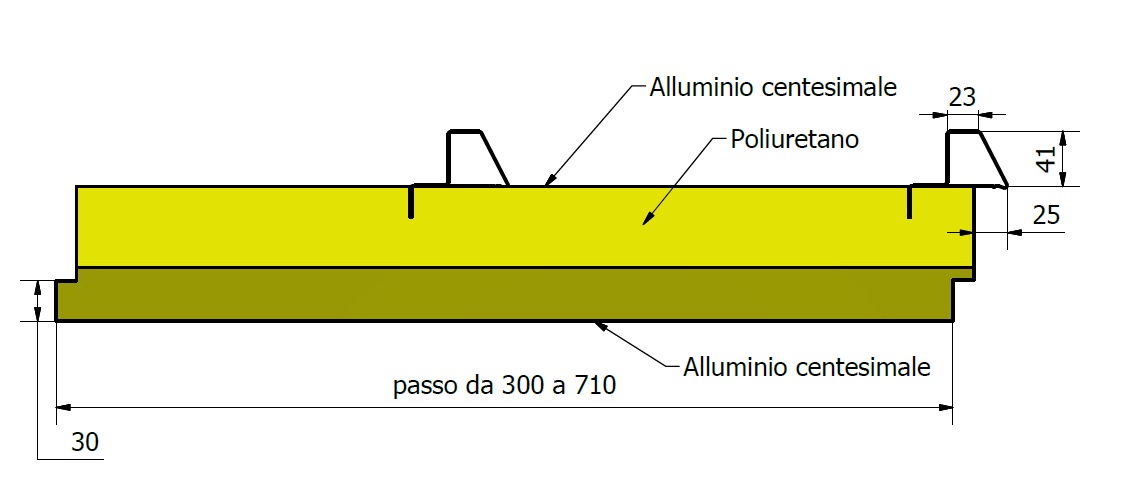

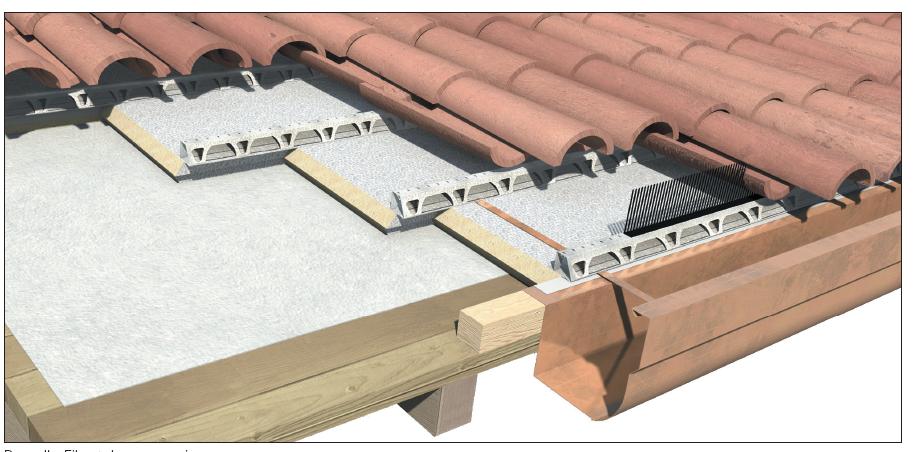

Fibrotek PLUS is the latest thermo-insulating panel developed by Fibrotubi technicians, which inserts a double stringer with an enlarged pitch size. Fibrotek Plus with double stringer reduces fixings during installation, and a reduction in material consumption, resulting in considerable cost savings. Fibrotek Plus halves the installation time ensuring a roof built in a very shorttime, particularly suitable for the installation of slate tiles and short /reduced pitch roofing from 300 to 710mm.

The laying System always provides for a panel with a pitch shorter than 280 mm (defined as a single Pitch) with a single stringer, followed by the other double stringer Plus panels with the pitch depending on the superstructure to be installed, tiles, rounded tiles, etc..

| Pitches that can be obtained | Extended pitch from 300 to 710 mm |

| Panel thicknesses | 60-80-100-120-140-160 mm |

TECHNICAL FEATURES

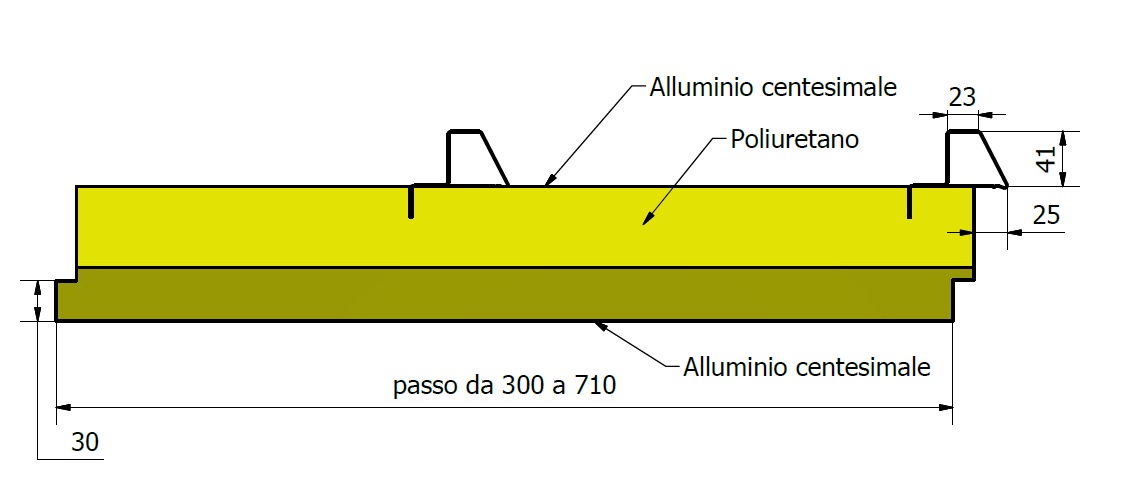

- Heat insulation in hard polyurethane foam, density: 39 Kg/m3, declared thermal conductivity : 0.020 W/mK;

- Embossed aluminium centesimal film enveloping the panel on all sides; it has the function of protecting the insulating material, waterproofing the covering and acts as a steam barrier;

- Aluzinc stringer, designed with the purpose of providing the right support to the covering while simultaneously guaranteeing excellent microventilation through the holes in the profile itself.

Fibrotek is crucial since it is able to adapt to all roof types and coverings in line with modern architecture dictates.

FUNCTIONAL FEATURES

ENERGY SAVING

FibroTek insulating body is made of high density rigid polyurethane foam, currently the material with the best thermal conductivity for the same thickness. As a consequence, the product easily meets the requirements of the Legislative Decree no. 311/06 and MD 26/01/2010, which identifies the transmittance values useful to obtain the tax deduction.

VENTILATION AND THERMAL INSULATION

The special design of the stringer provides a 4 cm thick ventilated chamber which ensures an optimum aeration flow, perfectly distributed under the entire covering, translating into:

– better living comfort thanks to the dispersal of the excessive heat accumulated in the summer and condensation in the winter;

– a longer life to the covering as it maintains similar conditions in terms of temperature and humidity between its intrados and extrados.

WATERPROOFING AND VAPOUR BARRIER

The embossed aluminium centesimal film that covers the insulating layer not only guarantees protection of the insulation against deterioration caused by contact with the air, but also acts as a brake to rising steam (at the bottom of the panel) and to possible infiltrations originating from the covering, letting the water flow through the holes in the metal stringers down to the gutter.

FibroTek works as a second waterproofing covering; in combination with the primary one given by the above combined roofing.

MECHANICAL STRENGTH

If the FibroTek panels are laid on a continuous structure (concrete and masonry flooring, wood boarding), they create a load bearing deck that can be walked all over. In the case of discontinuous supports (wood or steel beams) it is necessary to walk putting the feet on the metal stringers, avoiding the connection points between panels. The considerable section of the metal stringer has been designed to adequately support not just the walkover loads but also those of any installations for producing energy, such as photovoltaic or solar panel systems.

QUICK AND ECONOMICAL TO LAY

Laying the FibroTek panels is very quick thanks to the double edge profiling of the material that ensures precision and secure interlocking as well as extremely lightweight panels. Even the fixing of the covering is made easier and more secure thanks to the large supporting base on the metal stringer. But the economic advantage is no less important: compared to the past, in fact, the integration of the different layers in one panel (from the steam barrier to the metal stringers) guarantees a considerable saving when laying.

LAYING THE COVERING

The Fibro Tek system supports clay tiles, flat tiles, rounded tiles, cement tiles, slate sheets, corrugated or ribbed sheets in fibreglass, asbestos-cement or metal. The supporting stringer in aluzinc is, in fact, capable of adapting to the different laying and fixing requirements of covering materials, from the single tile locking tooth to the self-tapping fixings of the metal sheets.

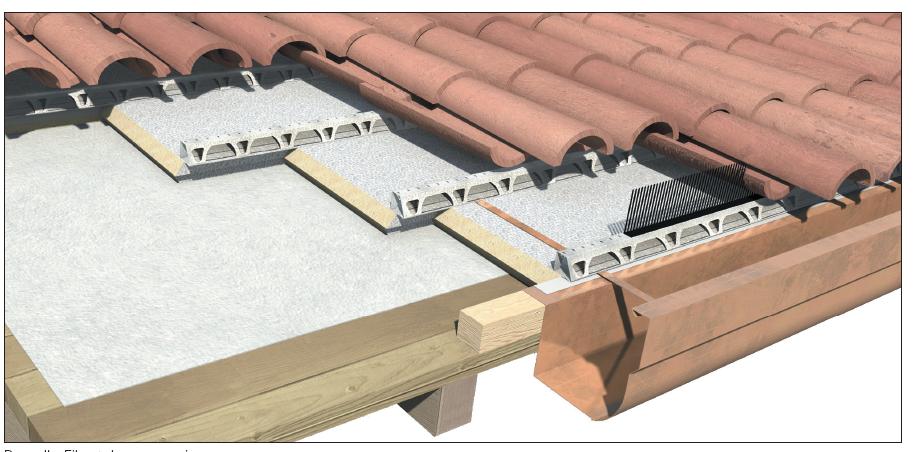

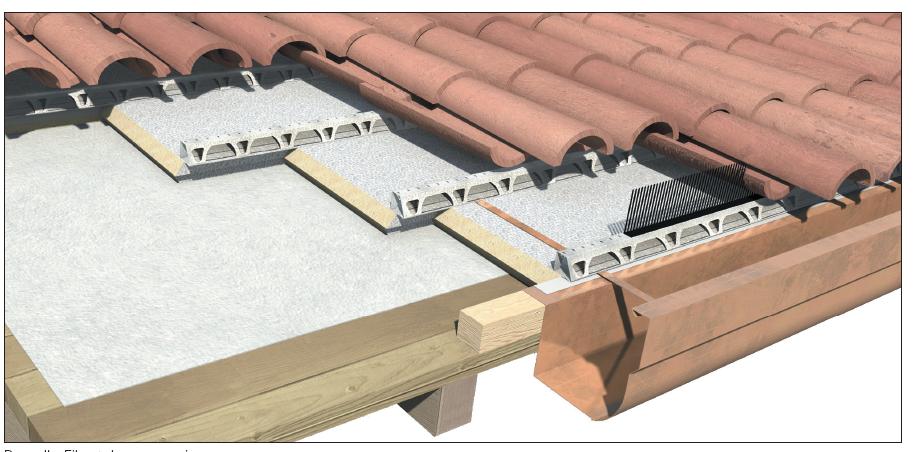

Fibrotek panel with rounded tiles

Fibrotek panel with french clay and Portugues tiles

Fibrotek panel with tiles

BRICK COVERING

The covering and Fibrotek panel are fixed together by simply putting the brick elements on the metal profile. In the case of particularly windy areas the tiles need to be fixed more effectively to the current stringer using the locking straps, which we supply, for passing through small holes made in the tiles themselves; this guarantees against the covering being blown off by the wind.

METAL SHEETS

Fibrotubi proposes in combination with Fibrotek its metal covering Tek 28, Il Coppo, Isocoppo and Coppo Corinzio. The panel-sheet fastening is carried out by means of self-tapping screws, according to the methods described in the technical data sheets of the individual products; in the case of metal coverings these must also be fastened to the underlying Fibrotek structure.

Fibrotek panel matched with Il Coppo

Fibrotek panel matched with Tek28 sheet

Fibrotubi can supply, besides the FibroTek panel, a set of accessories necessary for installing the product correctly, as described on the previous pages. These accessories guarantee sealing, fixing and complete the covering.

Firbopur polyurethane foam, 750 ml

(1 every 50 sqm approx.)

Fibroser Silicone sealant

(1 every 8 sqm approx.)

Fibroband adhesive tape in butyl aluminium, 100 mm

(1 every 30 smq approx.)

PVC comb bird screen, h 110 mm

(1 each linear metre)

Maxivent shaped stringer in Aluzinc

(length 3,940 mm)

Screw and dowel fixing

(1 per linear meter)

Firbopur polyurethane foam, 750 ml

(1 every 50 sqm approx.)

Ridge ventilation element galvanized steel with aluminium strips

Universal galvanized steel bracket for fastening the ventilation element and ridge under the roof, double function: ridge supports and also lath holders

Ventilated sheet metal and zinc/lead under roof ridge

For information about the product or to request a quote please fill out the form below.

Download Fibrotek CAD Objects

from the BIM portal

Fibrotek PLUS is the latest thermo-insulating panel developed by Fibrotubi technicians, which inserts a double stringer with an enlarged pitch size. Fibrotek Plus with double stringer reduces fixings during installation, and a reduction in material consumption, resulting in considerable cost savings. Fibrotek Plus halves the installation time ensuring a roof built in a very shorttime, particularly suitable for the installation of slate tiles and short /reduced pitch roofing from 300 to 710mm.

The laying System always provides for a panel with a pitch shorter than 280 mm (defined as a single Pitch) with a single stringer, followed by the other double stringer Plus panels with the pitch depending on the superstructure to be installed, tiles, rounded tiles, etc..

For information about the product or to request a quote please fill out the form below.

| Pitches that can be obtained | Extended pitch from 300 to 710 mm |

| Panel thicknesses | 60-80-100-120-140-160 mm |

TECHNICAL FEATURES

- Heat insulation in hard polyurethane foam, density: 39 Kg/m3, declared thermal conductivity : 0.020 W/mK;

- Embossed aluminium centesimal film enveloping the panel on all sides; it has the function of protecting the insulating material, waterproofing the covering and acts as a steam barrier;

- Aluzinc stringer, designed with the purpose of providing the right support to the covering while simultaneously guaranteeing excellent microventilation through the holes in the profile itself.

Fibrotek is crucial since it is able to adapt to all roof types and coverings in line with modern architecture dictates.

FUNCTIONAL FEATURES

ENERGY SAVING

FibroTek insulating body is made of high density rigid polyurethane foam, currently the material with the best thermal conductivity for the same thickness. As a consequence, the product easily meets the requirements of the Legislative Decree no. 311/06 and MD 26/01/2010, which identifies the transmittance values useful to obtain the tax deduction.

VENTILATION AND THERMAL INSULATION

The special design of the stringer provides a 4 cm thick ventilated chamber which ensures an optimum aeration flow, perfectly distributed under the entire covering, translating into:

– better living comfort thanks to the dispersal of the excessive heat accumulated in the summer and condensation in the winter;

– a longer life to the covering as it maintains similar conditions in terms of temperature and humidity between its intrados and extrados.

WATERPROOFING AND VAPOUR BARRIER

The embossed aluminium centesimal film that covers the insulating layer not only guarantees protection of the insulation against deterioration caused by contact with the air, but also acts as a brake to rising steam (at the bottom of the panel) and to possible infiltrations originating from the covering, letting the water flow through the holes in the metal stringers down to the gutter.

FibroTek works as a second waterproofing covering; in combination with the primary one given by the above combined roofing.

MECHANICAL STRENGTH

If the FibroTek panels are laid on a continuous structure (concrete and masonry flooring, wood boarding), they create a load bearing deck that can be walked all over. In the case of discontinuous supports (wood or steel beams) it is necessary to walk putting the feet on the metal stringers, avoiding the connection points between panels. The considerable section of the metal stringer has been designed to adequately support not just the walkover loads but also those of any installations for producing energy, such as photovoltaic or solar panel systems.

QUICK AND ECONOMICAL TO LAY

Laying the FibroTek panels is very quick thanks to the double edge profiling of the material that ensures precision and secure interlocking as well as extremely lightweight panels. Even the fixing of the covering is made easier and more secure thanks to the large supporting base on the metal stringer. But the economic advantage is no less important: compared to the past, in fact, the integration of the different layers in one panel (from the steam barrier to the metal stringers) guarantees a considerable saving when laying.

LAYING THE COVERING

The Fibro Tek system supports clay tiles, flat tiles, rounded tiles, cement tiles, slate sheets, corrugated or ribbed sheets in fibreglass, asbestos-cement or metal. The supporting stringer in aluzinc is, in fact, capable of adapting to the different laying and fixing requirements of covering materials, from the single tile locking tooth to the self-tapping fixings of the metal sheets.

Fibrotek panel with rounded tiles

Fibrotek panel with french clay and Portugues tiles

Fibrotek panel with tiles

BRICK COVERING

The covering and Fibrotek panel are fixed together by simply putting the brick elements on the metal profile. In the case of particularly windy areas the tiles need to be fixed more effectively to the current stringer using the locking straps, which we supply, for passing through small holes made in the tiles themselves; this guarantees against the covering being blown off by the wind.

METAL SHEETS

Fibrotubi proposes in combination with Fibrotek its metal covering Tek 28, Il Coppo, Isocoppo and Coppo Corinzio. The panel-sheet fastening is carried out by means of self-tapping screws, according to the methods described in the technical data sheets of the individual products; in the case of metal coverings these must also be fastened to the underlying Fibrotek structure.

Fibrotek panel matched with Il Coppo

Fibrotek panel matched with Tek28 sheet

Fibrotubi can supply, besides the FibroTek panel, a set of accessories necessary for installing the product correctly, as described on the previous pages. These accessories guarantee sealing, fixing and complete the covering.

Firbopur polyurethane foam, 750 ml

(1 every 50 sqm approx.)

Fibroser Silicone sealant

(1 every 8 sqm approx.)

Fibroband adhesive tape in butyl aluminium, 100 mm

(1 every 30 smq approx.)

PVC comb bird screen, h 110 mm

(1 each linear metre)

Maxivent shaped stringer in Aluzinc

(length 3,940 mm)

Screw and dowel fixing

(1 per linear meter)

Firbopur polyurethane foam, 750 ml

(1 every 50 sqm approx.)

Ridge ventilation element galvanized steel with aluminium strips

Universal galvanized steel bracket for fastening the ventilation element and ridge under the roof, double function: ridge supports and also lath holders

Ventilated sheet metal and zinc/lead under roof ridge

Download Fibrotek CAD Objects

from the BIM portal

Fibrotek PLUS is the latest thermo-insulating panel developed by Fibrotubi technicians, which inserts a double stringer with an enlarged pitch size. Fibrotek Plus with double stringer reduces fixings during installation, and a reduction in material consumption, resulting in considerable cost savings. Fibrotek Plus halves the installation time ensuring a roof built in a very shorttime, particularly suitable for the installation of slate tiles and short /reduced pitch roofing from 300 to 710mm.

The laying System always provides for a panel with a pitch shorter than 280 mm (defined as a single Pitch) with a single stringer, followed by the other double stringer Plus panels with the pitch depending on the superstructure to be installed, tiles, rounded tiles, etc..

| Pitches that can be obtained | Extended pitch from 300 to 710 mm |

| Panel thicknesses | 60-80-100-120-140-160 mm |

TECHNICAL FEATURES

- Heat insulation in hard polyurethane foam, density: 39 Kg/m3, declared thermal conductivity : 0.020 W/mK;

- Embossed aluminium centesimal film enveloping the panel on all sides; it has the function of protecting the insulating material, waterproofing the covering and acts as a steam barrier;

- Aluzinc stringer, designed with the purpose of providing the right support to the covering while simultaneously guaranteeing excellent microventilation through the holes in the profile itself.

Fibrotek is crucial since it is able to adapt to all roof types and coverings in line with modern architecture dictates.

FUNCTIONAL FEATURES

ENERGY SAVING

FibroTek insulating body is made of high density rigid polyurethane foam, currently the material with the best thermal conductivity for the same thickness. As a consequence, the product easily meets the requirements of the Legislative Decree no. 311/06 and MD 26/01/2010, which identifies the transmittance values useful to obtain the tax deduction.

VENTILATION AND THERMAL INSULATION

The special design of the stringer provides a 4 cm thick ventilated chamber which ensures an optimum aeration flow, perfectly distributed under the entire covering, translating into:

– better living comfort thanks to the dispersal of the excessive heat accumulated in the summer and condensation in the winter;

– a longer life to the covering as it maintains similar conditions in terms of temperature and humidity between its intrados and extrados.

WATERPROOFING AND VAPOUR BARRIER

The embossed aluminium centesimal film that covers the insulating layer not only guarantees protection of the insulation against deterioration caused by contact with the air, but also acts as a brake to rising steam (at the bottom of the panel) and to possible infiltrations originating from the covering, letting the water flow through the holes in the metal stringers down to the gutter.

FibroTek works as a second waterproofing covering; in combination with the primary one given by the above combined roofing.

MECHANICAL STRENGTH

If the FibroTek panels are laid on a continuous structure (concrete and masonry flooring, wood boarding), they create a load bearing deck that can be walked all over. In the case of discontinuous supports (wood or steel beams) it is necessary to walk putting the feet on the metal stringers, avoiding the connection points between panels. The considerable section of the metal stringer has been designed to adequately support not just the walkover loads but also those of any installations for producing energy, such as photovoltaic or solar panel systems.

QUICK AND ECONOMICAL TO LAY

Laying the FibroTek panels is very quick thanks to the double edge profiling of the material that ensures precision and secure interlocking as well as extremely lightweight panels. Even the fixing of the covering is made easier and more secure thanks to the large supporting base on the metal stringer. But the economic advantage is no less important: compared to the past, in fact, the integration of the different layers in one panel (from the steam barrier to the metal stringers) guarantees a considerable saving when laying.

LAYING THE COVERING

The FibroTek system supports clay tiles, flat tiles, rounded tiles, cement tiles, slate sheets, corrugated or ribbed sheets in fibreglass, asbestos-cement or metal. The supporting stringer in aluzinc is, in fact, capable of adapting to the different laying and fixing requirements of covering materials, from the single tile locking tooth to the self-tapping fixings of the metal sheets.

Fibrotek panel with rounded tiles

Fibrotek panel with french clay and Portugues tiles

Fibrotek panel with tiles

BRICK COVERING

The covering and Fibrotek panel are fixed together by simply putting the brick elements on the metal profile. In the case of particularly windy areas the tiles need to be fixed more effectively to the current stringer using the locking straps, which we supply, for passing through small holes made in the tiles themselves; this guarantees against the covering being blown off by the wind.

METAL SHEETS

Fibrotubi proposes in combination with Fibrotek its metal covering Tek 28, Il Coppo, Isocoppo and Coppo Corinzio. The panel-sheet fastening is carried out by means of self-tapping screws, according to the methods described in the technical data sheets of the individual products; in the case of metal coverings these must also be fastened to the underlying Fibrotek structure.

Fibrotek panel matched with Il Coppo

Fibrotek panel matched with Tek28 sheet

Fibrotubi can supply, besides the FibroTek panel, a set of accessories necessary for installing the product correctly, as described on the previous pages. These accessories guarantee sealing, fixing and complete the covering.

Firbopur polyurethane foam, 750 ml

(1 every 50 sqm approx.)

Fibroser Silicone sealant

(1 every 8 sqm approx.)

Fibroband adhesive tape in butyl aluminium, 100 mm

(1 every 30 smq approx.)

PVC comb bird screen, h 110 mm

(1 each linear metre)

Maxivent shaped stringer in Aluzinc

(length 3,940 mm)

Screw and dowel fixing

(1 per linear meter)

Firbopur polyurethane foam, 750 ml

(1 every 50 sqm approx.)

Ridge ventilation element galvanized steel with aluminium strips

Universal galvanized steel bracket for fastening the ventilation element and ridge under the roof, double function: ridge supports and also lath holders

Ventilated sheet metal and zinc/lead under roof ridge

For information about the product or to request a quote please fill out the form below.